Under the guidance of the "Dual Carbon" goals, hydrogen energy, as a vital component of clean energy, is embracing unprecedented development opportunities.As a holding subsidiary of Guangdong Anda Automation Solutions Co., Ltd.Anqing New Energy

Technology (Guangdong) Co., Ltd. specializes in the manufacturing of core hydrogen energy equipment, committed to providing global clients with high-performance, highly reliable smart manufacturing solutions for fuel cells and electrolyzers.

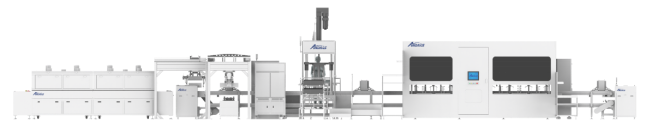

Membrane Electrode Assembly (MEA) Production Equipment

The Membrane Electrode Assembly is the "heart" of the fuel cell.Anqing New Energy has launched multiple precision equipment for MEA manufacturing:

Roll-to-Roll / Sheet-to-Sheet Catalyst Coating Machine: Utilizes slot-die coating technology to achieve a uniform coating layer with precision up to ±1µm, supporting online inspection.

CCM Hot-Transfer Equipment: Enables high-efficiency catalyst transfer with a membrane shrinkage rate of ≤2%, improving utilization and consistency.

5-in-1 / 7-in-1 Lamination Machine: Employs high-precision CCD visual alignment to achieve bubble-free and wrinkle-free lamination, compatible with various adhesive materials and sizes.

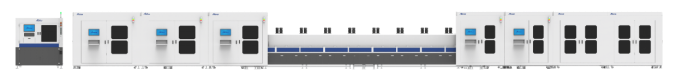

Bipolar Plate (BPP) Manufacturing and Sealing

Metal Bipolar Plate Welding Line: Integrates laser welding, leak testing, and AGV loading/unloading to achieve fully automated production.

Sealing Coating Line: Features glue line uniformity inspection and automatic cleaning functions, ensuring reliable sealing without leakage or dripping.

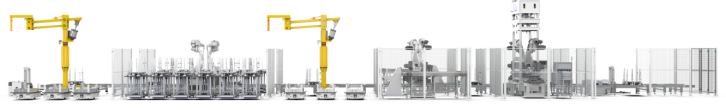

Stack Assembly and Testing

Fuel Cell Stack Assembly Line: Supports 20-ton pressing, laser marking, and leak testing, with repeatability of ±0.04 sccm, meeting the demands of mass production.

MEA Leak Testing Station: Employs a dual-mode method (Flow Rate & Pressure Hold) to accurately determine sealing performance and ensure nondestructive testing of the MEA

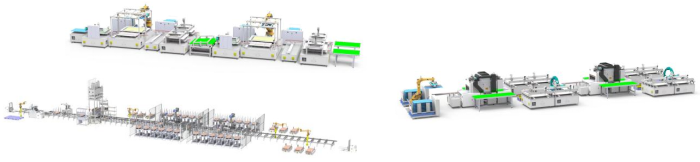

PEM water electrolysis for hydrogen production has become a mainstream pathway for green hydrogen production due to its advantages such as rapid start-stop and high current density. Anqing New Energy has launched the following equipment for PEM electrolyzers:

Ultrasonic Spraying Equipment: Utilizes pulse spraying and vacuum adsorption to effectively prevent proton exchange membrane swelling, with slurry utilization >95%.

CCM Hot-Transfer and Lamination Equipment: Building on the expertise in fuel cell processes, it is adapted for large-format CCM manufacturing in electrolyzers.

Stack Assembly Line: Features a maximum pressing force of 200 tons, supports fully automatic stacking and leak testing, facilitating the efficient integration of electrolyzers.

Focusing on flow battery energy storage,Anqing provides the following core equipment support:

Printing, Curing and Lamination Line: Features fully automatic loading and unloading, a flexible design compatible with multi-size products, and a lamination accuracy ≤ ±0.3mm.

Dispensing Curing Line and Stack Assembly Line: Integrated UV curing and leak detection ensure frame sealing and stacking reliability.

Anqing New Energy is also proactively expanding into SOEC (Solid Oxide Electrolysis Cell) equipment,pushing high-temperature electrolysis technology from demonstration to practical application, thereby facilitating diversified development of the hydrogen energy sector.

Leveraging the extensive expertise in industrial automation from its parent company,

Anqing has established a comprehensive smart equipment portfolio covering three key areas: fuel cells, electrolyzers, and flow batteries. From material coating to stack integration, from testing and validation to complete production line delivery,Anqing is leveraging technological innovation and precision manufacturing to empower the global hydrogen industry in advancing towards a new phase characterized by scalability, cost-effectiveness, and high performance.

Hydrogen Empowers the Future,Anqing Powers Your Journey.

电话

手机

微信

公众号

抖音